In cleanrooms, where precision and sterility are non-negotiable, the efficiency of airflow is a critical factor that directly influences product quality. To enhance this efficiency, the deployment of airflow visualisation machines has become a standard practice due to the level of precision and ease offered by these devices. Let us explore the instrumental role of these machines in cleanroom optimisation to look at why renting machines for airflow visualisation is a highly worthwhile investment.

Understanding Cleanroom Efficiency

Cleanrooms, by definition, are controlled environments where the level of pollutants, airborne particles, and microbes is meticulously regulated. These environments are prevalent in industries such as pharmaceuticals, electronics, and healthcare, where even the slightest deviation from cleanliness standards can lead to significant consequences.

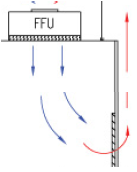

At the heart of cleanroom efficiency lies the intricate dance of airflow. The controlled movement of air within these environments ensures the removal of contaminants, maintaining the required level of cleanliness. Achieving optimal airflow is a complex challenge, necessitating tools that go beyond theoretical models.

The Role of Airflow Visualisation Machines

In the pursuit of cleanroom optimisation, airflow visualisation has become increasingly popular. For this purpose, operators can rely on machines for airflow visualisation to map out and illustrate the airflow within cleanrooms. These machines provide a visual representation of how air moves through a controlled environment, offering insights that traditional testing methods might miss. By making the invisible visible, these machines empower cleanroom operators to identify potential issues and optimise airflow for enhanced efficiency.

The Impact on Cleanroom Efficiency

Identifying Contamination Sources

One of the primary benefits of utilising machines for airflow visualisation is the ability to identify contamination sources. These machines create a visual map of airflow patterns, revealing areas where contaminants may linger or infiltrate the cleanroom. By pinpointing these sources, operators can implement targeted solutions, ensuring a more efficient removal of pollutants.

Enhancing Design and Layout

Airflow visualisation machines play a crucial role in optimising the design and layout of cleanrooms. They provide real-time data on how changes in infrastructure, equipment placement, or room configuration affect airflow patterns. This information is invaluable in designing cleanrooms that not only meet but exceed efficiency expectations.

The Intersection with Compressed Air Quality Testing

While airflow visualisation machines focus on the dynamics of air movement, their role intersects with compressed air quality testing in maintaining overall cleanroom integrity. Compressed air, often used in cleanrooms, can introduce contaminants if not of the highest quality. An integrated approach that combines airflow visualisation with compressed air quality testing ensures a holistic evaluation of cleanroom conditions.

Compressed air quality testing is a crucial step in the optimisation process. It involves assessing the purity of the compressed air used in cleanrooms, identifying potential contaminants, and ensuring that the air meets the stringent standards required for cleanroom operations. The synergy between airflow visualisation and compressed air quality testing establishes a comprehensive framework for maintaining cleanroom efficiency.

Guarantee Airflow Purity with Cleanzones

Airflow visualisation testing from Cleanzones comes with the added benefit of our expert guidance and support. Our team of specialists not only provides the necessary equipment, but also offers insights and recommendations based on years of experience in cleanroom optimisation for various industry verticals.

This collaborative approach ensures that clients maximise the potential of airflow visualisation for their specific cleanroom requirements. Contact Cleanzones today for accurate and reliable airflow visualisation, and elevate your standards with our precision and expertise.