What to Expect During an Indoor Air Quality Assessment for Cleanroom Certification

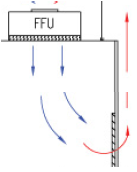

Indoor air quality assessments are critical for ensuring that cleanrooms meet stringent standards required for various industries, including pharmaceuticals, biotechnology, and electronics. These assessments are a part of the cleanroom certification process, which guarantees that the cleanroom environment is free from contaminants that could compromise product quality or safety. Here is a brief outline of what you can expect during an indoor air quality assessment for cleanroom certification, highlighting key procedures such as airflow visualisation testing. Understanding Cleanroom Certification Cleanroom certification is a rigorous process that validates whether a controlled environment meets the specified requirements for air cleanliness, temperature, humidity, and other factors. Certification is essential for maintaining compliance with industry regulations and ensuring the safety and efficacy of products manufactured in these environments. Cleanroom certification services provide comprehensive evaluations that include various tests and inspections. These services ensure that cleanrooms operate within the desired parameters and are free from harmful particulates. The certification process typically involves multiple stages, including initial assessments, testing, and ongoing monitoring. Pre-Assessment Preparation Before the actual indoor air quality assessment begins, there is a significant amount of preparation involved. Cleanroom certification services often start with a thorough review of the cleanroom’s design, construction, and operational protocols. This review helps identify potential areas of concern that need to be addressed prior to testing. The preparation phase may also involve: Calibration of Instruments: Ensuring all testing equipment is properly calibrated for accurate results. Site Survey: Conducting a preliminary inspection to familiarise the assessment team with the cleanroom layout and its systems. Documentation Review: Gathering and reviewing all relevant documents, including previous certification reports, maintenance records, and standard operating procedures. Key Components of the Indoor Air Quality Assessment Particulate Testing One of the primary components of an indoor air quality assessment is particulate testing. This involves measuring the concentration of airborne particles within the cleanroom to ensure they do not exceed acceptable levels. Cleanroom certification services use high-precision instruments to count and classify particles of different sizes, typically ranging from 0.1 to 5.0 micrometres. Airflow Visualisation Testing Airflow visualisation testing is a crucial aspect of cleanroom certification. This test evaluates the air movement within the cleanroom to ensure that it follows the designed airflow patterns. Proper airflow is essential to prevent contamination by swiftly removing particulates and maintaining a sterile environment. During airflow visualisation testing, technicians use smoke or vapour to visualise the air currents. This allows them to identify any areas where airflow might be insufficient or turbulent, which could lead to contamination. By addressing these issues, cleanroom certification services help maintain the integrity of the cleanroom environment. HEPA Filter Integrity Testing High-Efficiency Particulate Air (HEPA) filters are critical components in maintaining cleanroom air quality. HEPA filter integrity testing ensures that these filters are functioning correctly and effectively capturing contaminants and preventing their release into the cleanroom. This test involves checking for leaks or damages in the filters and verifying that they meet performance standards. Environmental Monitoring Continuous environmental monitoring is another important element of the indoor air quality assessment. This involves the use of sensors and data loggers to track various parameters such as temperature, humidity, and pressure. These parameters must be kept within specific ranges to ensure the cleanroom’s optimal performance. Microbial Testing In addition to particulate and airflow testing, microbial testing is conducted to detect the presence of viable microorganisms in the cleanroom. This is particularly important in industries where even the smallest microbial contamination can have significant consequences. Samples are collected from air and surfaces and then cultured to identify and quantify any microbial presence. Post-Assessment Activities After the indoor air quality assessment, the cleanroom certification services provider will compile a detailed report outlining the findings. This report includes data from all the tests conducted, Addressing Non-Compliance Issues After the cleanroom testing is conducted, the data collected will be presented in the report, allowing the client to determine whether their controlled environment meets the required specifications. If any issues are identified during the assessment, the client can consult with professionals from Cleanzones to discuss potential solutions, which may involve: Reconfiguring Airflow Systems: Adjusting or redesigning airflow systems to eliminate turbulence or dead spots. Enhancing Filtration: Replacing, upgrading, or repairing HEPA filters to improve air quality. Implementing Better Practices: Training staff on proper cleanroom protocols to reduce the risk of contamination. Ongoing Monitoring and Maintenance Achieving cleanroom certification is not a one-time event; it requires ongoing monitoring and maintenance. Regular inspections and assessments help ensure that the cleanroom continues to meet certification standards. Cleanroom certification services often offer maintenance plans that include periodic testing and recalibration of services. Cleanzones: The Full Range of Cleanroom Certification Services For cleanroom certification services that guarantee results with precise and comprehensive testing procedures, choose Cleanzones. Our wealth of experience in securing cleanroom certification for operations across multiple verticals makes us uniquely positioned among firms that provide cleanroom certification services in Singapore.